|

|

|

|

|

|

|

|

|

|

1. Delivery

of timber to an object diameter of 24 to 30cm. |

|

|

2. Sanding

the wood by hand |

|

|

3. Calibration

logs power planer “REBIR” |

|

|

4. Polishing

sander logs (different emery sheets). Here the canopy is required, protection

from rain. |

|

|

5.

View logs after a "primary" grinding - finished polished timber. |

|

|

6. Foundation

for a bath and shed her prepared |

|

|

7. Starts cutting log. |

|

|

|

|

|

9. Laying

timber with an insulating material. |

|

|

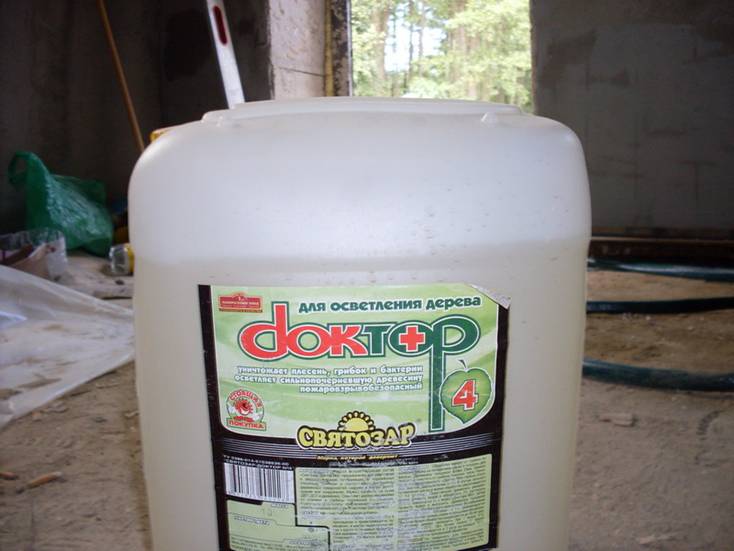

10. The

logs are processed by means of protection - first, "Dr. 4" and then

"Doctor-5" |

|

|

11.«

8 rims log». |

|

|

12. The

quality of calibration and polishing on wooden house. |

|

|

13. Well,

"included" corners, as well as see the "work" means of

protection - there is no "blue." |

|

|

14. The

tent protects the timber from the rain - for polishing. |

|

|

15. 9

crowns log - view from the back side. |

|

|

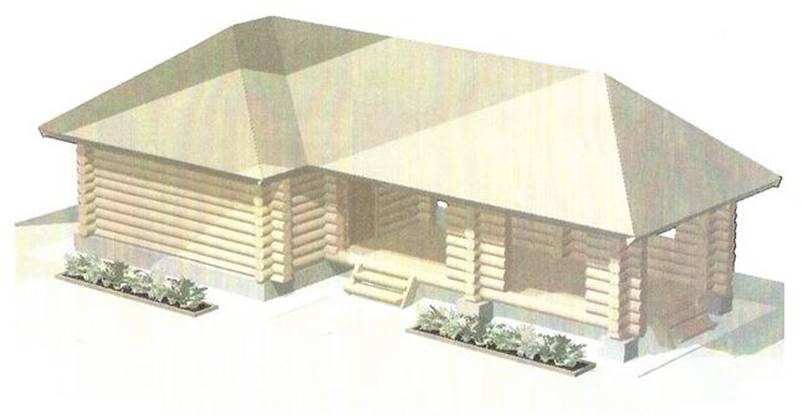

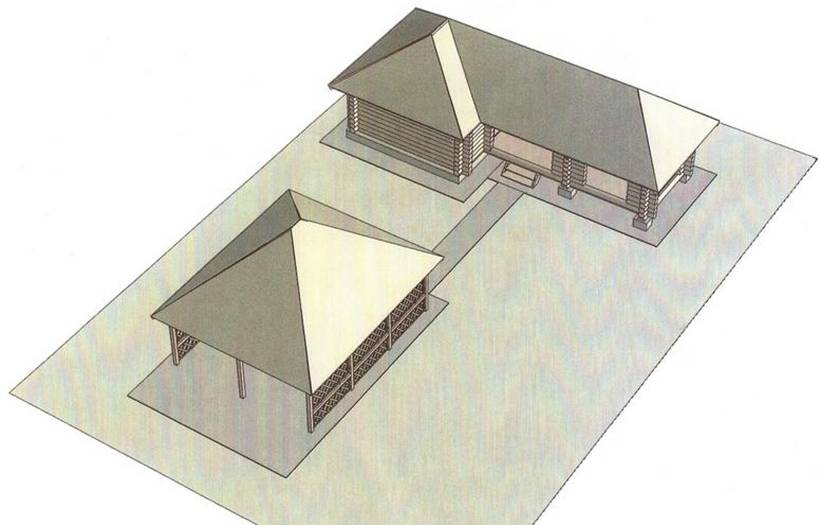

16. Planned

type bath with a canopy. |

|

|

17. Install furring. |

|

|

18. Preparing

the foundation for a canopy of beams for cars. |

|

|

19. Kickoff rafters. |

|

|

20. Polished

boards overhang, a means of treated and colorless drevohronom - stacked in a

tent |

|

|

21. Ready

crate bath with a canopy. |

|

|

22. Type

of sheathing from the inside and the "open" canopy. |

|

|

23. Import cane roofing. |

|

|

24. The

first bundles of reeds on the roof - will be 30cm thick. This roof insulation

is not necessary (it is very warm), the roof "breathes", gutters

are not required nepozharoopasna - the effect of "pressure-books",

and 50-year warranty. |

|

|

25. Reed covered (thickness |

|

|

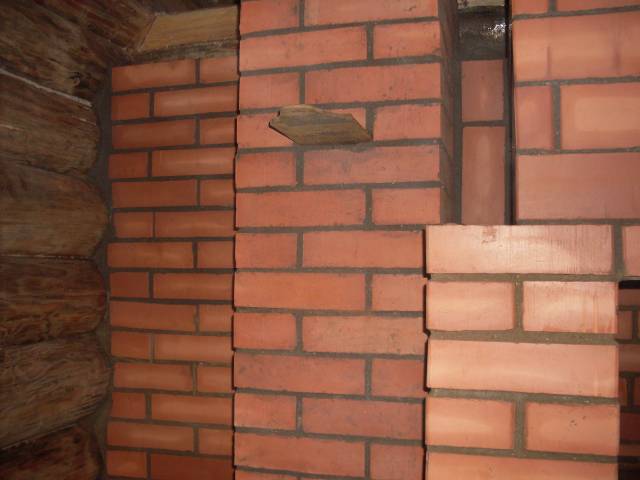

26.

Furnace steel in a bath |

|

|

27. Carport 28. Carport, covered

katapalom, ready |

|

|

29. Bath and is painted finishing |

|

|

|

|

We offer our one object - a house of logs on hand harvesting in Porec

|

|

|

|

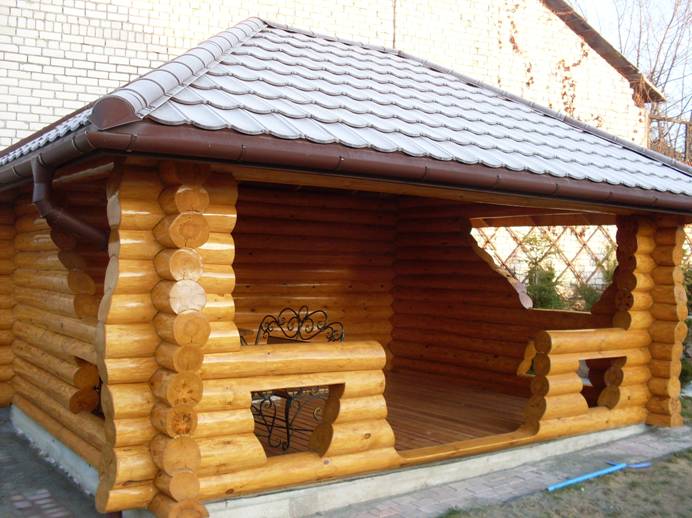

Arbour

manual felling |

|

Please

note that we do share, which the cost of the manual log cabin is the cheapest

compared to other wooden houses - an average of 300 euros per

To

export up to 400 euro for 1m3.